Bestuur en naleving

European Cleaning Machines Recycling (ECMR) streeft continu naar het demonteren van haar product ontvangsten met respect voor het milieu, investeert in de ontwikkeling van duurzame oplossingen en technologieën, voor materialen die eenvoudig ontmanteld en gerecycled kunnen worden voor hergebruik op een zodanige wijze dat het gehele productieproces een lage milieu-impact heeft op de duurzaamheid naar hernieuwde grondstoffen.

Het vervoer, het laden en de behandeling van reinigingsmachines en apparatuur is zoveel mogelijk geoptimaliseerd en wordt georganiseerd op de meest duurzame wijze ter vermindering van de CO2 -uitstoot. Terwijl aan het einde van de levensduur van machines en apparatuur deze worden geretourneerd voor behandeling, garandeert ECMR duurzame werkmethodes waarbij zowel middelen en methodieken worden gebruikt om hun volledige voordeel van hernieuwde energiebronnen tot stand te brengen en onafhankelijk kunnen worden aangepast voor de productie van nieuwe producten en onnodige afvalverwijdering daarmee wordt voorkomen.

Dankzij de vastgelegde procedures van de demontage en recycling verwerking door ECMR, alsmede de scheiding van de verschillende onderdelen, wordt altijd in een optimaal resultaat voorzien om tot een maximaal hergebruik van producten te komen en biedt zij maximale prestaties, door het scheiden van de onderdelen en componenten voor de recycling voorbereiding en minimalisering van de afvalstromen. ECMR documenteert het demontage- en recyclingproces zodat naderhand een certificaat afgegeven wordt, welke het bewijs van duurzaam hergebruik vormt.

“WIJ DEMONTEREN, RECYCLE EN UPCYCLE”

Door een juiste beoordeling van de milieu-impact naar hernieuwde product toepassingen met herbruikbare grondstoffen, demonteren en recyclen wij de materialen te gebruiken voor hergebruik.

| – ABS onderdelen | 100% recyclebaar / upcycle |

| – Aluminium onderdelen | 100% recyclebaar |

| – Elektrische kabels | 96% recyclebaar |

| – Elektrische componenten / Motoren | 69% recyclebaar |

| – Ferro metalen | 100% recyclebaar |

| – Gegalvaniseerde metalen | 100% recyclebaar |

| – Kunststof / Rubber | 84% recyclebaar / upcycle |

| – Polycarbonaat | 100% recyclebaar / upcycle |

| – Polyethyleen | 92% recyclebaar / upcycle |

| – Batterijen | 100% recyclebaar / hergebruik |

NALEVING

-

TRANSPORT

- optimale lading capaciteit materialen

- transport rationalisering (combinatie transporten)

-

DEMONTAGE, RECYCLE, UPCYCLE

- bevorderen van het hergebruik van recyclebare materialen

- ontwikkeling van duurzame technologieën naar verbetermodellen tot hergebruik

- componenten rationalisering

-

PRODUCTIE

- ISO14001:2004 gecertificeerde productie en verwerkingsuitvoering

- ISO 26000 gecertificeerd ingebed in de MVO prestatieladder

- vereenvoudiging van demontage handelingen

- verificatie van juiste absorptie en hernieuwde toepassingsgebieden voor hergebruik van materialen

-

HERGEBRUIK

- identificatie van de ideale demontage procedures

- toepassing van duurzame technologieën naar verbetermodellen

-

VERWIJDERING

- minimalisering van afgewerkte materialen en afvalstroom verwijdering

- registreert relevante gegevens en verstrekt rapporten volgens geldende wet- en regelgeving

-

CERTIFICERING MACHINE INNAME

- verstrekt certificaat verklaringen inzake historie van machine type en inname verwerking

-

FACILITEREN

- verbindt markpartners en stakeholders naar optimalisering van en naar duurzame oplossingen ter bevordering van ecologische voordelen tot circulair ondernemen

1. JURIDISCHE REFERENTIES

In de volgende paragrafen, informeren wij u, hoe de demontage van elk component

van de machine- en apparatenbouw, gebaseerd op de samenstelling, wordt gescheiden

voor recycling, overeenkomstig de relevante Europese richtlijnen die van kracht

zijn in elk land afzonderlijk.

De geldende richtlijnen met betrekking tot recycling van materialen zijn:

- Richtlijn 08/98/EG van de Raad van de Europese Gemeenschap op afval

- Richtlijn 91/156/EEG van de Raad van de Europese Gemeenschap op de niet-gevaarlijke afvalstromen

Volgens de bovengenoemde richtlijnen moeten de afvalstoffen nuttig worden toegepast in een van de volgende manieren:

- Hoofdgebruik als brandstof of andere middelen voor het genereren van energie

- Oplosmiddel terugwinning/regeneratie

- Recycling/terugwinning van organische stoffen die niet als oplosmiddelen worden gekenmerkt

- Recycling/terugwinning van metalen en metaalverbindingen

- Recycling/terugwinning van andere anorganische materialen

- Regeneratie van zuren of basen

- Terugwinning van bestanddelen die zijn gebruikt voor terugdringen van verontreinigingen

- Terugwinning van bestanddelen uit katalysatoren

- Olie re-raffinage of andere recyclebare olie bestanddelen

- Landbehandelingsgebruik in het voordeel voor de landbouw of ecologische verbetering

- Gebruik van afvalstoffen die zijn verkregen uit één van de onder [R1] t/m [R10] genummerde toepassingsrichtlijnen

- R12 Uitwisseling van afvalstoffen ter onderwerping aan de handelingen onder [R1] t/m [R 11] genummerde toepassingsrichtlijnen

- R13 Opslag van afvalstoffen in afwachting van één van de onder [R1] tot en met [R12] genummerde toepassingsrichtlijnen

(met inbegrip van voorlopige opslag voorafgaande aan inzameling op de plaats waar het is gedemonteerd)

INHOUD

2.1 ABS onderdelen

2.2 Aluminium onderdelen

2.3 Elektrische kabels

2.4 Elektrische componenten / motoren

2.5 Ferro metaal onderdelen

2.6 Gegalvaniseerde metaal onderdelen

2.7 Kunststof / Rubber gebaseerde componenten

2.8 Polycarbonaat componenten

2.9 Polyethyleen componenten

2.10 Batterijen

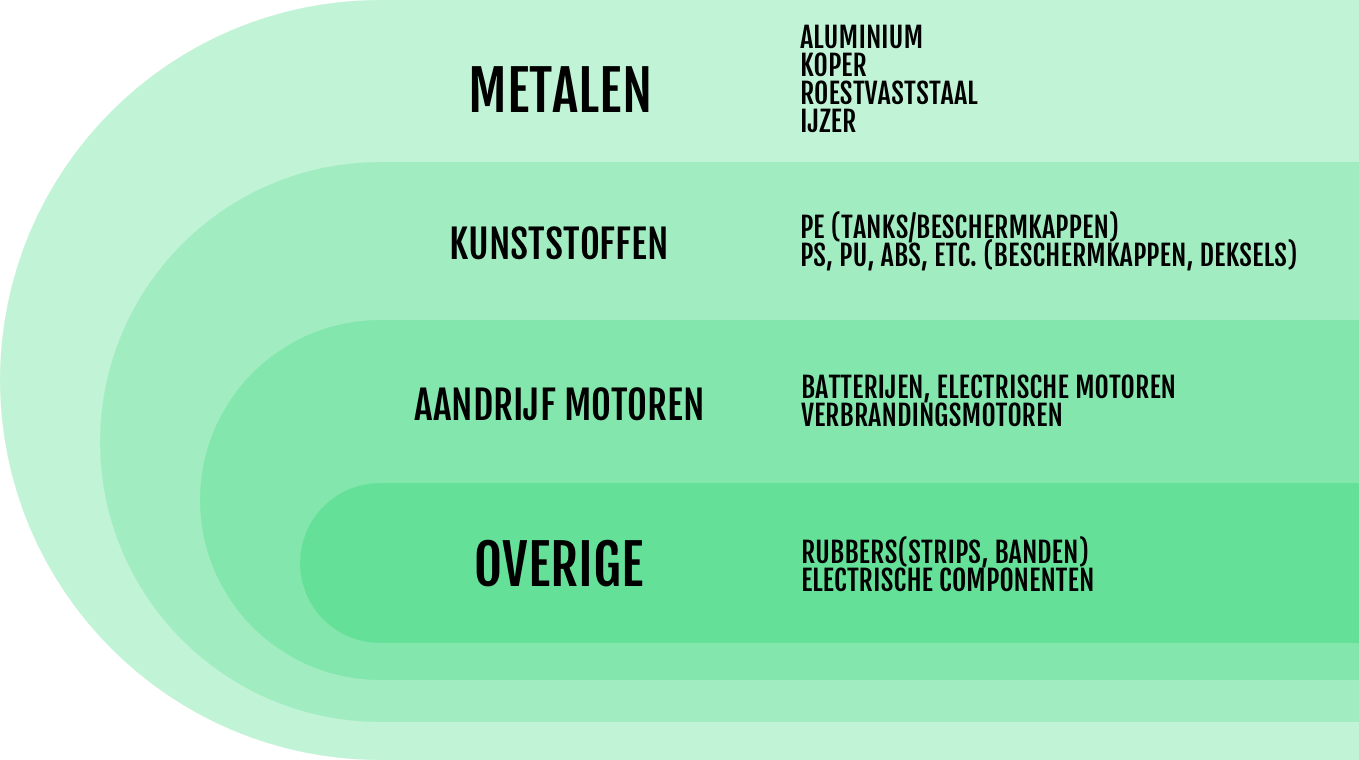

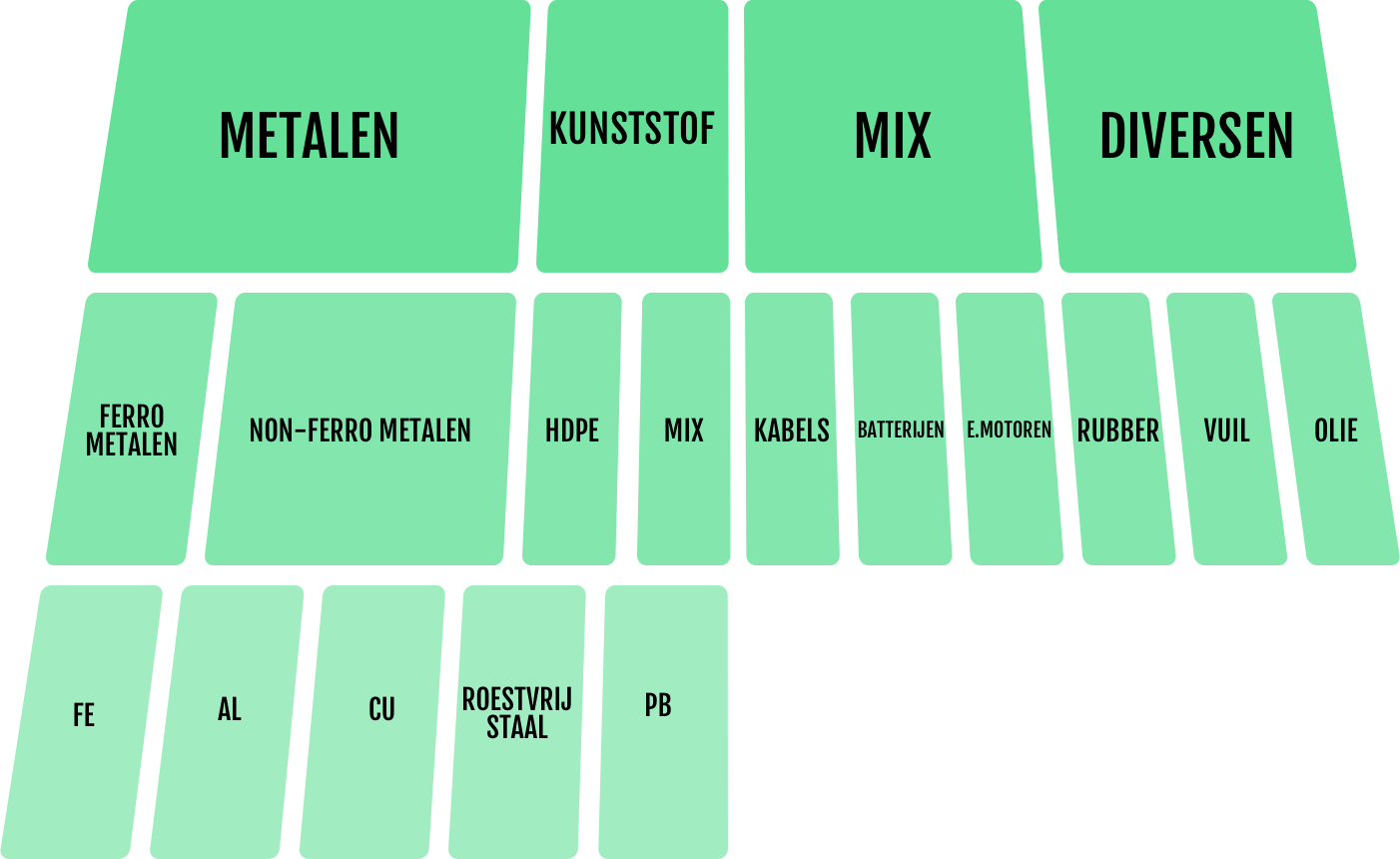

2. DE MATERIALEN VAN WAARUIT DE DEMONTAGE VOOR RECYCLING, HERGEBRUIK & UPCYCLE TOT STAND WORDT GEBRACHT

2.1 ABS ONDERDELEN

Deze categorie omvat alle onderdelen gemaakt voor carrosserie of beschermkappen in ABS.

Bijvoorbeeld: dispensers, vacuüms, hogedrukreinigers en dashboards.

DEZE WORDEN ONTMANTELD EN GESCHEIDEN VOOR RECYCLING OP DE VOLGENDE MANIER:

- opgeslagen met materiaal identificering, verwerking en afscheiding van de eventueel verontreinigende stoffen niet hiertoe behoren[R13]

TE VERKRIJGEN VOOR ECONOMISCH HERGEBRUIK:

- secundaire grondstof in meestal gecommercialiseerde vormen

2.2 ALUMINIUM ONDERDELEN

Alle onderdelen van de machines die zijn opgebouwd uit aluminium en zijn legeringen, behoren tot deze categorie. Bijvoorbeeld: zuigmond, zuigmond systemen en schijf

machine stuurkolommen.

DEZE WORDEN ONTMANTELD EN GESCHEIDEN VOOR RECYCLING OP DE VOLGENDE MANIER:

- opgeslagen met materiaal identificering, verwerking en afscheiding van de eventueel verontreinigende stoffen [R13]

- directe terugwinning t.b.v. de metaalverwerkende industrie [R4]

- opslag voor de eliminatie van stoffen niet hiertoe behorend [R13]

TE VERKRIJGEN VOOR ECONOMISCH HERGEBRUIK:

- secundaire grondstof voor de metaalverwerkende industrie

- aluminium legeringen in meestal gecommercialiseerde vormen

2.3 ELEKTRISCHE KABELS

Deze categorie omvat alle kabels die lopen langs de machines en zijn samengesteld uit koperen geleiders en voorzien zijn van hittebestendige kunststof covers.

DEZE WORDEN ONTMANTELD EN GESCHEIDEN VOOR RECYCLING OP DE VOLGENDE MANIER:

- opgeslagen en verwerking voor het verwijderen van de kunststof isolatie. Slijpen en korreling van het rubber, de granulatie van het metaal voor regeneratie in de metaalverwerkende industrie [R13]

TE VERKRIJGEN VOOR ECONOMISCH HERGEBRUIK:

- directe terugwinning t.b.v. de metaalverwerkende industrie [R4]

- kunststof en rubber grondstoffen in meestal gecommercialiseerde vormen

- koper en lood in meestal gecommercialiseerde vormen

2.4.ELECTRISCHE COMPONENTEN / MOTOREN

Deze categorie omvat: de zuigkracht van de motoren, borstel motoren, tractie-motoren, aandrijvingen en printplaten.

DEZE WORDEN ONTMANTELD EN GESCHEIDEN VOOR RECYCLING OP DE VOLGENDE MANIER:

- opgeslagen met identificering, verwerking en afscheiding van de eventueel verontreinigende stoffen [R13]

- demontage voor scheiding van de herbruikbare componenten (koper van de aandrijvingen, metalen uit het element en de kunststoffen van de covers)

TE VERKRIJGEN VOOR ECONOMISCH HERGEBRUIK:

- wat is opgegeven in de beschrijvingen van de individuele apparatuur voor de afzonderlijke materialen

2.5 FERRO METAAL ONDERDELEN

Alle onderdelen van de machines die bestaan uit een metaalachtig materiaal, gespoten in grijs of zwart, behoren tot deze categorie. Bijvoorbeeld: het frame, chassis en de steun van de zuigmond.

DEZE WORDEN ONTMANTELD EN GESCHEIDEN VOOR RECYCLING OP DE VOLGENDE MANIER:

- directe terugwinning t.b.v. de metaalverwerkende industrie [R4]

- opslag voor de eliminatie van stoffen niet hiertoe behorend [R13]

TE VERKRIJGEN VOOR ECONOMISCH HERGEBRUIK:

- ferro metalen of legeringen in meestal gecommercialiseerde vormen

- ferro anorganische zouten (zuurrest-ionen) in meestal gecommercialiseerde vormen

- secundaire grondstoffen t.b.v. de metaalverwerkende industrie

2.6 GEGALVANIZEERDE METAAL ONDERDELEN

Deze categorie verwijst naar alle delen van de machines, samengesteld uit metalen bekleed met zink, nikkel on- en gepolijst. Bijvoorbeeld: hefbomen, katrollen en assen.

DEZE WORDEN ONTMANTELD EN GESCHEIDEN VOOR RECYCLING OP DE VOLGENDE MANIER:

- directe terugwinning t.b.v. de metaalverwerkende industrie [R4]

- opslag voor de eliminatie van stoffen niet hiertoe behorend [R13]

TE VERKRIJGEN VOOR ECONOMISCH HERGEBRUIK:

- ferro metalen of legeringen in meestal gecommercialiseerde vormen

- ferro anorganische zouten (zuurrest-ionen) in meestal gecommercialiseerde vormen

- secundaire grondstoffen voor de metaalverwerkende industrie

2.7 KUNSTSTOF / RUBBER GEBASEERDE COMPONENTEN

Componenten gemaakt van rubber of derivaten daarvan behoren tot deze categorie. bijvoorbeeld: handgrepen, beschermkappen en motor carters.

DEZE WORDEN ONTMANTELD EN GESCHEIDEN VOOR RECYCLING OP DE VOLGENDE MANIER:

- terugwinning t.b.v. de rubberindustrie voor samen te voegen mixen [R3]

- terugwinning in de productie van bitumen [R3]

- opslag voor eliminatie van vreemde stoffen niet hiertoe behorend [R13]

TE VERKRIJGEN VOOR ECONOMISCH HERGEBRUIK:

- producten in rubber in meestal gecommercialiseerde vormen

- bitumen en spatborden in meestal gecommercialiseerde vormen

2.8 POLYCARBONAAT COMPONENTEN

Alle onderdelen van polycarbonaat gemaakt, behoren tot deze categorie. Bijvoorbeeld: dispenser platen, ramen, randen, verlichtingskappen en dashboard armaturen.

DEZE WORDEN ONTMANTELD EN GESCHEIDEN VOOR RECYCLING OP DE VOLGENDE MANIER:

- opgeslagen met materiaal identificering, verwerking en afscheiding van de eventueel verontreinigende stoffen niet hiertoe behorend [R13]

TE VERKRIJGEN VOOR ECONOMISCH HERGEBRUIK:

- secundaire grondstof in meestal gecommercialiseerde vormen

2.9 POLYETHYLEEN COMPONENTEN

Alle onderdelen van polyethyleen gemaakt behoren tot deze categorie. Bijvoorbeeld: de brandstoftanks, watertanks en carrosserieën van sommige machines en apparaten.

DEZE WORDEN ONTMANTELD EN GESCHEIDEN VOOR RECYCLING OP DE VOLGENDE MANIER:

- opgeslagen met materiaal identificering, verwerking en afscheiding van de eventueel verontreinigende stoffen niet hiertoe behorend [R13]

TE VERKRIJGEN VOOR ECONOMISCH HERGEBRUIK:

- secundaire grondstof in meestal gecommercialiseerde vormen

2.10 BATTERIJEN

Deze categorie van machineonderdelen zijn samengesteld uit gevaarlijke stoffen.

DEZE WORDEN ONTMANTELD EN GESCHEIDEN VOOR RECYCLING EN/OF HERGEBRUIK OP DE VOLGENDE MANIER:

- opgeslagen t.b.v. hergebruik rest capaciteit > 50% (R1)

- volledige component voor hergebruik in ecosystemen (R1)

- secundaire montage voor hergebruik [R4] – [R7]

TE VERKRIJGEN VOOR ECONOMISCH HERGEBRUIK:

- directe terugwinning t.b.v. de energie industrie

- directe terugwinning t.b.v. de metaalverwerkende industrie

3. CERTIFICERINGEN

3.1 KWALITEIT EN MILIEU

ISO 14001-2004

De officiële erkenning garandeert dat de milieu-impact van het bedrijf onder stringente controle wordt gehouden en een voortdurende inspanning levert om deze te verminderen.

3.2 BELEID EN STRUCTUUR

ISO 26000

Bewaakt de organisatie ten aanzien van haar prestaties met betrekking tot de samenleving waarin de onderneming actief is en het effect ervan op het milieu en zowel in- als extern worden gemeten op de algemene prestaties en haar ondernemend vermogen om effectief te blijven functioneren.

4. LIDMAATSCHAPPEN

4.1 MVO NEDERLAND

MVO Nederland is het Centre of Excellence voor Nederlandse & Europese bedrijven die continu streven naar maatschappelijk verantwoord ondernemen. Meer dan 2000 bedrijven in Nederland zijn aangesloten bij deze netwerk organisatie.

4.2 VERENIGING AFVALBEDRIJVEN

Het platform voor het volledige spectrum van industriële, commerciële, overheids- en openbare belangen behartiging die relevant zijn voor het beheer van afvalstoffen. Verricht onderzoek en lobbyen voor een gezond en evenwichtig ondernemersklimaat in Nederland en Europa en bevordering van efficiënt, praktisch en duurzaam afvalbeheer.

4.3 ISSA (Wereldwijde Cleaning Industrie Vereniging)

Wereldwijd toonaangevende vereniging die de belangen behartigd voor de schoonmaak industrie en de markt van hygiëne in al haar geledingen continu professionaliseert en duurzame samenwerkingen hierin faciliteert.

4.4 NIWO NEDERLAND (National & Internationaal Wegvervoer Organisatie)

De NIWO verleent licenties voor de Nederlandse transportsector en heeft als doel het bevorderen van de goede werking van de markt zowel op het binnenlandse als grensoverschrijdend vervoer van goederen over de weg.